Ensure general maintenance and housekeeping standards are met

Version 1 - Last updated 23rd July 2025

A supplier should implement the following activities in the facility.

Maintenance and housekeeping

- Identify and record machines requiring maintenance.

- Schedule and track maintenance activities.

- Regularly inspect and label all chemical containers.

- Check for and remove expired chemicals from use.

- Verify the functionality of all first-aid boxes and eye showers.

- Replace or repair non-functional equipment immediately.

Housekeeping SOP

A supplier should prepare and maintain a housekeeping SOP that includes:

- Identifying and documenting machinery, components and equipment not performing optimally.

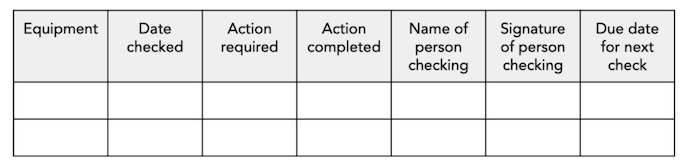

- Maintaining records as per standard operating procedures. (Refer to the template given below to track general maintenance and housekeeping).

- Scheduling and carrying out the replacement of machinery, components, PPE, equipment, first-aid box components, spill kits and store materials according to their expiry dates.

- Maintaining detailed records of all machinery and equipment servicing activities. Inspecting and identifying chemical containers that are in poor condition, unlabelled, or expired.

- Ensuring timely replacement or disposal of such containers.

- Implementing procedures for the safe disposal of unused or rejected chemical products.

- Conducting regular chemical clean-outs to manage and minimise hazardous waste.

- Regularly reviewing and updating the emergency response measures, including eyewash stations, body showers, exit signs, assembly points, exit pathways, fire safety equipment, and first-aid boxes.

The below template can be used for tracking general maintenance and housekeeping: