Sample and test wastewater

This is the new version of Wastewater & Sludge Guidelines

This version (V2) is published and available to prepare for. It will replace the active version (V1) and take effect from 01 Nov 2026. Until then, continue using Wastewater & Sludge Guidelines V1. View Changelog

How wastewater is sampled and tested depends on the discharge type and industrial wastewater flow rate.

Suppliers are categorised into five ZDHC discharge types for sampling and testing wastewater.

Discharge types

- Direct discharge

- Indirect discharge with pretreatment (with sludge)

- Indirect discharge with pretreatment (without sludge)

- Indirect discharge without pretreatment

- Zero Liquid Discharge (ZLD)

Flow rate and threshold limits

Facilities that generate equal to or more than 15m3 of wastewater per day are required to meet more requirements than those that generate less than 15m3 per day.

This is because suppliers that generate less than 15m3 of wastewater per day (for example, screen printing facilities that wash moulds, screens and tools) do not impact the environment in the same way as those that generate more than or equal to 15m3 of wastewater per day (such as a typical dye house or tanneries).

The threshold wastewater average discharge applies to suppliers irrespective of the supplier's production type or production processes.

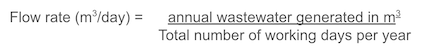

Flow rate calculation

Wastewater quality requirements

The parameters to be monitored for wastewater quality are:

- ZDHC MRSL substances: To check for intentional use of ZDHC MRSL substances and/or high levels of respective contamination in chemical inputs.

- Heavy metals: Must be monitored in the direct discharge and indirect discharge categories only.

- Conventional parameters and anions: Must be monitored in the direct discharge category only.

Direct discharge generates ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters.

- Sample discharged wastewater and test for heavy metal parameters.

- Sample discharged wastewater and test for conventional and anions parameters.

Indirect discharge with pretreatment (with sludge) ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters.

- Sample discharged wastewater and test for only arsenic, cadmium, chromium (VI), lead and mercury parameters.

Indirect discharge with pretreatment (without sludge) ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters.

- Sample discharged wastewater and test for only arsenic, cadmium, chromium (VI), lead and mercury parameters.

Indirect discharge without pretreatment ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters.

- Sample discharged wastewater and test for only arsenic, cadmium, chromium (VI), lead and mercury parameters.

Zero Liquid Discharge (ZLD) ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters.

Direct discharge generates <15m3 industrial wastewater per day

- Sample discharged wastewater and test for heavy metal parameters.

- Sample discharged wastewater and test for conventional and anions parameters.

Indirect discharge with pretreatment (with sludge) <15m3 industrial wastewater per day

No requirement

Indirect discharge with pretreatment (without sludge) <15m3 industrial wastewater per day

No requirement

Indirect discharge without pretreatment <15m3 industrial wastewater per day

No requirement

Zero Liquid Discharge (ZLD) <15m3 industrial wastewater per day

No requirement

Sampling procedure of wastewater and sludge at the facility

The ZDHC Approved Wastewater Laboratory will request a 10 day (including weekends, but excluding public holidays) production window from the facility. Upon receiving this request, the facility is required to specify the specific days within that window during which production activities will occur at its peak. This timeframe will then be designated as the sampling window.

During the sampling window, the ZDHC Approved Wastewater Laboratory reserves the right to perform sampling on any production day without specifying the exact date in advance. This process follows a semi-announced sampling approach, ensuring both operational feasibility and the integrity of the sampling process is maintained.

The facility will be notified that a sampler from a ZDHC Approved Wastewater Laboratory may visit at any point during the declared production days, and should be prepared to accommodate and to extend co-operation to the sampler for sampling purposes.

Reporting

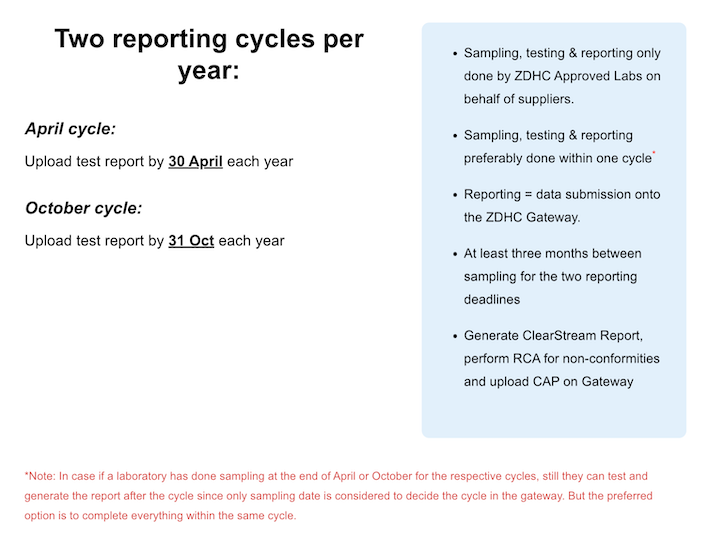

Once testing is completed by the ZDHC Approved Wastewater Laboratory the supplier must generate a ClearStream Report on the ZDHC Gateway for the April cycle and October cycles.

Implementation

ZDHC wastewater quality requirements must be implemented through sampling and testing of the wastewater at a facility twice a year through a ZDHC Approved Wastewater Laboratory.

- Suppliers should find a ZDHC Approved Wastewater Laboratory using Find your Expert

- Initiate sampling and testing.

- Sampling before 30 April and before 31 October every year to meet the cycle timelines.

- There should be at least a 3-month gap between the two sampling and testing cycles.

- The wastewater test reports for the 2 cycles must be uploaded to the supplier’s ZDHC Gateway account by the ZDHC Approved Wastewater Laboratory, completing the sampling and testing.

For further training, suppliers should visit the ZDHC Academy

Candidate List

The ZDHC Wastewater and Sludge Candidate List signals intended changes to future updates of the guidelines. This list aims to give the industry an advanced indication of what to expect in future updates and, therefore, give the industry enough time to prepare for them, thereby facilitating wide-scale industry adoption and implementation.

There is no mandatory requirement to conduct testing, do a Root Cause Analysis (RCA), or develop a Corrective Action Plan (CAP) for Candidate List entries, but it is strongly advised that a proactive approach be adopted.

| Parameter | Intention |

|---|---|

| Effluent toxicity | To check the aquatic toxicity effects of substances that may not appear on the ZDHC MRSL, it is intended to evaluate the impact of wastewater discharge to the environment and biodiversity through water toxicity indicators. |

| Smart, intelligent testing grid | ZDHC intends to review the current wastewater testing protocol and transition to a pragmatic approach that incentivises input chemical management through ZDHC MRSL conformance of chemical inputs (InCheck). For this approach, a smart testing grid based on substrate, chemical and process-specific risks would be required. |

| Water use targets for leather | ZDHC intends to set water use targets for the textile and leather processes that take into account the complexities of the operations (in terms of the production processes, substrate of fibres, types of thickness of hides and absorption, material to liquor ratio, type of the machinery used, inefficiencies, reuse of water, etc.) These targets will be categorised into Level 0, 1, 2, and 3 to outline a continuous improvements journey for suppliers. |

| Load-based calculation for key conventional parameters | Currently, the ZDHC Wastewater and Sludge Guidelines allows reporting of conventional parameters only on a concentration basis (mg/ltr). ZDHC plans to introduce load-based limits (g/kg of material produced) for some conventional parameters linked to ZDHC water use targets. This approach will support facilities on - Tracking reduction in total effluent load over time, even if concentration levels vary due to changes in water usage. - Support in decision-making for improvements in ETP design and operational control. |