Sample and test wastewater

How wastewater is sampled and tested depends on the discharge type and industrial wastewater flow rate.

Scope for wastewater guidelines

ZDHC is not yet a legal requirement in any country. These guidelines align with multiple brand-specific testing requirements for wastewater and sludge. However, some of the parameters will help the suppliers to align with the wastewater legal requirements of specific countries.

This doesn’t mean that complying with the below parameters guarantee compliance with the wastewater legal requirements of any country.

The guidellines apply to discharged industrial wastewater and sludge produced from wastewater treatment operations of textile, apparel, leather and footwear suppliers with wet processing facilities. This includes, but is not limited to:

- Dyeing and finishing of fibres, yarns, threads, fabrics, garments, textile trims and laces

- Fabric mills

- Laundry, washing and finishing facilities

- Printing facilities

- Vertical finished goods manufacturing facilities where any wet processes occur

- Synthetic materials (synthetic fibres or textile-polymer composite microfibres) coated with PU, PVC or similar polymers that hold the appearance of leather but are not made from animal skin or hide.

- With reference to leather:

- Raw materials include: Hides from animal origin

- Facility type tanning process includes:

- Beamhouse and tanning: including soaking, liming, removal of extraneous tissues, unhairing and fleshing, deliming, bating, pickling, pre-tanning, etc.

- Wet-end, crusting and/or finishing: such as washing, degreasing, re-tanning, dyeing, fat liquoring, oiling, coating etc.

These guidelines do not currently apply to wastewater discharge from suppliers including, but not limited to:

- Accessories or trim manufacturers e.g. zips, buttons (plastic metal, glass, shells etc ) and galvanising processes

- Cotton farming

- Cattle ranching

- Polymer production

- Raw wool scouring

- Production of chemicals or mixing of chemical formulations for commercial sale

In addition, the wastewater guidelines do not currently apply to:

- Discharge of domestic wastewater only. Such as:

- From a sewing/garmenting (e.g. staking) facility that employs workers but has no in-house wet processing unit.

- Domestic wastewater that is not blended with industrial wastewater.

- Wastewater management and treatment systems beyond the property boundaries of the supplier. This includes any third-party, off-site, centralised or common effluent treatment plants (CETP) that are not under the direct control and/or ownership of the supplier.

- CETPs can choose to monitor their performance against these guidelines.

- Any supplier who discharges to CETP is deemed an indirect supplier and should test against these guidelines.

- With reference to leather:

- Slaughter houses

- Leather facilities with only mechanical processes/phases e.g. only embossing, polishing, staking or dry milling.

Separate wastewater guidelines are available for Man-Made Cellulosic Fibres (MMCF) suppliers.

Discharge types

Suppliers are categorised into five ZDHC discharge types for sampling and testing wastewater:

- Direct discharge

- Indirect discharge with pretreatment (with sludge)

- Indirect discharge with pretreatment (without sludge)

- Indirect discharge without pretreatment

- Zero Liquid Discharge (ZLD)

Flow rate and threshold limits

Facilities that discharge equal to more than 15m3 of wastewater per day are required to meet more requirements than those who discharge less than 15m3. This is because suppliers that discharge less than 15m3 of wastewater per day (for example, screen printing facilities that wash moulds, screens, and tools) do not impact the environment in the same way as those who discharge more than or equal to 15m3 of wastewater per day (such as a typical dye house or tanneries).

The threshold wastewater average discharge applies to suppliers irrespective of the supplier's production type or production processes.

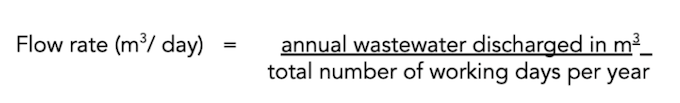

Flow rate calculation

Wastewater quality requirements

The parameters to be monitored for wastewater quality are:

- ZDHC MRSL substances: To check for intentional use of ZDHC MRSL substances and/or high levels of respective contamination in chemical inputs.

- Heavy metals: Must be monitored in direct discharge and indirect discharges categories only.

- Conventional parameters and anions: Must be monitored in direct discharge category.

Direct discharge generates ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters

- Sample discharged wastewater and test for heavy metal parameters

- Sample discharged wastewater and test for conventional and anions parameters

Indirect discharge with pretreatment (with sludge) ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters

- Sample discharged wastewater and test for test only arsenic, cadmium, chromium (VI), lead, mercury parameters

Indirect discharge with pretreatment (without sludge) ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters

- Sample discharged wastewater and test for test only arsenic, cadmium, chromium (VI), lead, mercury parameters

Indirect discharge without pretreatment ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters

- Sample discharged wastewater and test for test only arsenic, cadmium, chromium (VI), lead, mercury parameters

Zero Liquid Discharge (ZLD) ≥15m3 industrial wastewater per day

- Sample untreated wastewater and test for MRSL parameters

Direct discharge generates <15m3 industrial wastewater per day

- Sample discharged wastewater and test for heavy metal parameters

- Sample discharged wastewater and test for conventional and anions parameters

Indirect discharge with pretreatment (with sludge) <15m3 industrial wastewater per day

No requirement

Indirect discharge with pretreatment (without sludge) <15m3 industrial wastewater per day

No requirement

Indirect discharge without pretreatment <15m3 industrial wastewater per day

No requirement

Zero Liquid Discharge (ZLD) <15m3 industrial wastewater per day

No requirement

Reporting

Once testing is completed by the ZDHC Approved Wastewater Laboratory the supplier must generate a ClearStream report on the ZDHC Gateway.

Implementation

ZDHC wastewater guidelines must be implemented through sampling and testing of the wastewater at a facility twice a year through a ZDHC Approved Wastewater Laboratory.

- Suppliers should find a ZDHC Approved Wastewater Laboratory using Find your Expert

- Initiate sampling and testing.

- Sampling before 30 April and before 31 October every year to meet the cycle timelines.

- There should be at least a 3-month gap between the two sampling and testing cycles.

- The wastewater test reports for the 2 cycles must be uploaded to the supplier’s ZDHC Gateway account by the ZDHC Approved Wastewater Test Laboratory completing the sampling and testing.

For further training suppliers should visit the ZDHC Academy